In today’s competitive and asset-intensive industries, organizations rely heavily on effective asset and equipment management to maintain productivity, control costs, and ensure long-term sustainability. From manufacturing plants and hospitals to logistics companies and utilities, physical assets such as machinery, vehicles, IT infrastructure, and facilities represent significant investments. Managing these assets effectively requires a structured and strategic approach known as physical asset lifecycle management.

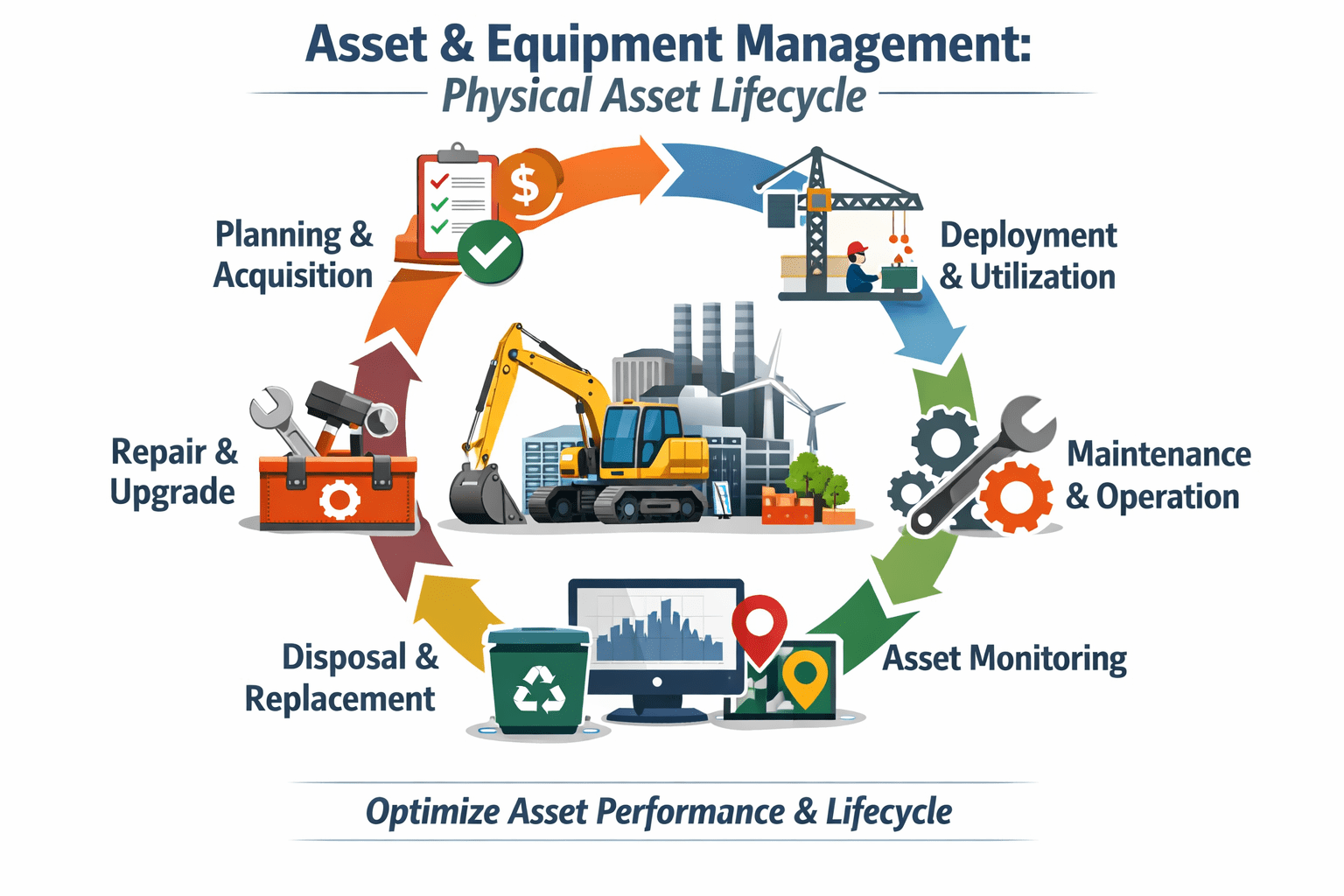

Physical asset lifecycle management (PALM) is a comprehensive framework that oversees assets from initial planning and acquisition through operation, maintenance, and final disposal. When implemented correctly, it enables organizations to maximize asset value, reduce downtime, improve safety, and support data-driven decision-making.

This article provides a professional and practical overview of physical asset lifecycle management and explains why it is a critical component of modern asset and equipment management strategies.

What Is Physical Asset Lifecycle Management?

Physical asset lifecycle management refers to the systematic management of physical assets throughout their entire life. It ensures that every stage of an asset’s existence contributes to business goals while minimizing risks and costs.

The asset lifecycle typically consists of five key stages:

- Planning and design

- Acquisition and installation

- Operation and utilization

- Maintenance and optimization

- Decommissioning and disposal

Each stage requires different processes, tools, and stakeholders, but all must align under a single asset management strategy.

The Importance of Physical Asset Lifecycle Management

Organizations that adopt physical asset lifecycle management gain several competitive advantages:

- Improved asset performance and reliability

- Lower total cost of ownership (TCO)

- Better regulatory compliance and safety

- Reduced unplanned downtime

- Enhanced capital investment decisions

Rather than treating assets as isolated tools, PALM views them as long-term resources that support organizational value creation.

Stage 1: Planning and Design

The lifecycle begins with planning. This stage focuses on defining business needs, technical requirements, and expected asset performance.

Key activities include:

- Identifying asset requirements

- Conducting cost-benefit analysis

- Evaluating risk and compliance needs

- Designing asset specifications

- Forecasting lifecycle costs

Effective planning ensures that assets are selected not just based on purchase price, but on long-term performance, maintainability, and scalability.

This is also where organizations define key performance indicators (KPIs) such as availability, utilization, and reliability targets.

Stage 2: Acquisition and Installation

Once requirements are defined, the next phase is acquiring and deploying the asset.

Key considerations include:

- Vendor selection and contract management

- Procurement processes

- Asset tagging and documentation

- Installation and commissioning

- Integration with existing systems

At this stage, it is essential to establish accurate asset records within a computerized maintenance management system (CMMS) or enterprise asset management (EAM) platform. Proper documentation ensures traceability and supports future maintenance and audits.

Stage 3: Operation and Utilization

During the operational phase, assets deliver their primary business value. This stage focuses on maximizing performance while minimizing risk and cost.

Key operational practices include:

- Monitoring asset usage and condition

- Training operators and users

- Tracking performance metrics

- Ensuring compliance with safety standards

Data collected during this phase helps organizations identify inefficiencies, underutilized assets, and potential failure risks.

Operational analytics and IoT-based monitoring tools are increasingly used to gain real-time insights into asset health and productivity.

Stage 4: Maintenance and Optimization

Maintenance is the most critical stage in physical asset lifecycle management. It determines how long assets remain reliable and cost-effective.

There are four main maintenance strategies:

1. Reactive Maintenance

Fixing assets only after failure. This approach is risky and costly, often leading to extended downtime.

2. Preventive Maintenance

Scheduled maintenance based on time or usage. This reduces failures but may result in unnecessary work.

3. Predictive Maintenance

Uses sensor data and analytics to predict failures before they occur.

4. Prescriptive Maintenance

Advanced systems recommend specific actions based on predictive insights.

A mature asset and equipment management program combines predictive and preventive approaches to balance cost and reliability.

Stage 5: Decommissioning and Disposal

Eventually, every asset reaches the end of its useful life. This stage focuses on safe and cost-effective retirement.

Key activities include:

- Evaluating asset condition and residual value

- Planning replacement or upgrade

- Compliance with environmental regulations

- Secure data removal (for IT assets)

- Recycling or resale

Proper disposal protects organizations from legal risks and helps recover value through resale or recycling.

Role of Technology in Asset Lifecycle Management

Technology plays a central role in modern physical asset lifecycle management.

Key systems include:

- CMMS (Computerized Maintenance Management Systems)

- EAM (Enterprise Asset Management software)

- IoT sensors and digital twins

- AI-driven analytics platforms

These tools enable:

- Centralized asset data

- Automated maintenance scheduling

- Real-time condition monitoring

- Predictive failure analysis

- Lifecycle cost tracking

Digital transformation allows organizations to shift from reactive asset management to intelligent, data-driven strategies.

Benefits of Physical Asset Lifecycle Management

Implementing PALM delivers measurable business value across industries.

Financial Benefits

- Lower capital and operational costs

- Improved return on assets (ROA)

- Reduced emergency repairs

Operational Benefits

- Increased uptime and productivity

- Better resource allocation

- Improved planning accuracy

Strategic Benefits

- Smarter capital investments

- Stronger compliance posture

- Enhanced organizational resilience

Common Challenges and How to Overcome Them

Despite its benefits, many organizations struggle with asset lifecycle management.

Data Silos

Disconnected systems prevent visibility.

Solution: Integrate CMMS, ERP, and IoT platforms.

Poor Asset Data Quality

Incomplete or outdated records reduce decision accuracy.

Solution: Implement standardized data governance.

Cultural Resistance

Teams may resist new tools and processes.

Solution: Invest in training and change management.

Budget Constraints

Short-term cost focus undermines long-term value.

Solution: Use lifecycle costing to justify investments.

Best Practices for Effective Asset and Equipment Management

To achieve success with physical asset lifecycle management, organizations should adopt these best practices:

- Align asset strategy with business objectives

- Maintain accurate and centralized asset data

- Use predictive analytics and automation

- Implement condition-based maintenance

- Regularly review asset performance metrics

- Train staff on asset management principles

ISO 55000 standards provide an excellent framework for structuring asset management systems and ensuring continuous improvement.

Future Trends in Physical Asset Lifecycle Management

The future of asset and equipment management is increasingly digital and intelligent.

Key trends include:

- AI-powered predictive maintenance

- Digital twins for real-time simulation

- Blockchain for asset traceability

- Sustainability-focused lifecycle planning

- Autonomous maintenance systems

Organizations that embrace these innovations will gain a significant competitive edge.

Conclusion

Physical asset lifecycle management is no longer optional for modern organizations. It is a strategic discipline that transforms asset and equipment management from a reactive cost center into a proactive value driver.

By managing assets across their entire lifecycle—from planning and acquisition to maintenance and disposal—organizations can optimize performance, reduce risk, and achieve long-term operational excellence.

In a world where efficiency, reliability, and sustainability define success, physical asset lifecycle management stands as one of the most critical pillars of modern business operations.