In asset-intensive organizations, maintenance is no longer just a technical support function—it is a strategic driver of operational excellence. Whether in manufacturing, healthcare, facilities management, or utilities, the ability to measure maintenance performance accurately has a direct impact on reliability, cost control, safety, and business continuity. This is where maintenance performance metrics play a critical role.

Industry service guides outline proven maintenance KPI frameworks used to measure maintenance effectiveness and align technical activities with business goals.

This article provides a comprehensive and professional explanation of maintenance performance metrics, why they matter, and how organizations can use them to improve efficiency, reduce downtime, and support data-driven decision-making.

What Are Maintenance Performance Metrics?

Maintenance performance metrics are quantitative indicators used to evaluate how effectively maintenance activities are executed. These metrics provide insight into the performance of maintenance processes, asset reliability, workforce productivity, and cost efficiency.

In practical terms, maintenance performance metrics answer essential questions such as:

- Are assets being maintained proactively or reactively?

- How often do failures occur?

- How long does it take to restore equipment?

- Are maintenance resources being used efficiently?

Without performance metrics, maintenance decisions are based on assumptions rather than evidence.

Why Maintenance Performance Metrics Matter?

Maintenance typically accounts for a significant portion of operational budgets. Poorly measured maintenance results in:

- Increased unplanned downtime

- Higher operating costs

- Safety incidents

- Shortened asset lifespan

- Reduced service quality

Effective maintenance performance metrics enable organizations to:

- Identify inefficiencies

- Prioritize critical assets

- Justify maintenance investments

- Improve workforce planning

- Support compliance and audit requirements

Ultimately, performance measurement transforms maintenance from a cost center into a value-generating function.

Core Categories of Maintenance Performance Metrics

Maintenance performance metrics are generally grouped into four main categories.

1. Reliability and Availability Metrics

These metrics focus on how often assets fail and how reliably they operate.

Key reliability metrics include:

- Mean Time Between Failures (MTBF) – Average time between equipment failures.

- Mean Time to Repair (MTTR) – Average time required to restore an asset after failure.

- Availability Rate – Percentage of time an asset is operational.

- Failure Frequency – Number of failures over a defined period.

Purpose:

To measure asset stability and reduce operational disruptions.

2. Maintenance Planning and Scheduling Metrics

These metrics evaluate how well maintenance work is organized.

Common indicators include:

- Preventive Maintenance (PM) Compliance Rate – Percentage of scheduled PM tasks completed on time.

- Planned vs Unplanned Maintenance Ratio – Balance between proactive and reactive work.

- Schedule Adherence – Percentage of work orders completed as scheduled.

- Work Order Backlog – Volume of outstanding maintenance tasks.

Purpose:

To improve maintenance maturity and shift toward proactive operations.

3. Cost and Financial Metrics

These metrics focus on cost efficiency and budget control.

Key financial metrics include:

- Maintenance cost as a percentage of asset replacement value

- Maintenance cost per unit of output

- Labor cost ratio

- Spare parts inventory turnover

Purpose:

To ensure maintenance delivers maximum value with minimal waste.

4. Workforce and Productivity Metrics

These metrics assess how effectively maintenance personnel perform.

Examples include:

- Technician utilization rate

- Labor hours per work order

- Overtime percentage

- Training compliance rate

Purpose:

To optimize workforce performance and resource allocation.

Leading vs Lagging Maintenance Metrics

High-performing organizations distinguish between two types of metrics:

Lagging Indicators

These measure historical performance, such as total downtime or maintenance cost.

Leading Indicators

These predict future performance, such as PM completion rate or inspection frequency.

Relying only on lagging indicators results in reactive management. Leading indicators allow organizations to prevent problems before they occur.

How to Design Effective Maintenance Performance Metrics?

Not all metrics create value. Effective maintenance metrics should follow these principles:

1. Align with Business Objectives

Metrics should support broader goals such as reliability, cost control, safety, and customer satisfaction.

2. Focus on Critical Assets

Not all equipment deserves the same level of measurement. Critical assets should receive priority.

3. Keep Metrics Simple and Actionable

If a metric cannot drive a decision or improvement action, it has limited value.

4. Standardize Definitions

Consistent definitions prevent misinterpretation and ensure data integrity.

Using Maintenance Metrics for Decision-Making

Maintenance performance metrics enable better decisions across multiple areas:

Asset Management

Metrics identify underperforming assets and justify repair, overhaul, or replacement decisions.

Budget Planning

Historical data supports accurate forecasting and resource allocation.

Risk Management

Failure trends highlight safety and compliance risks.

Continuous Improvement

Metrics support root cause analysis and process optimization.

When integrated into Computerized Maintenance Management Systems (CMMS), metrics provide real-time operational intelligence.

Common Mistakes in Maintenance Performance Measurement

Many organizations fail to realize the full value of performance metrics due to common errors.

Measuring Too Many Metrics

Excessive metrics create noise and dilute focus.

Poor Data Quality

Inaccurate asset records undermine all performance analysis.

Lack of Ownership

Metrics without accountability do not drive improvement.

No Link to Action

Metrics should always result in corrective or preventive actions.

Performance measurement must be embedded into daily operations, not treated as a reporting exercise.

Maintenance Metrics and Predictive Technologies

Modern maintenance performance measurement increasingly relies on:

- IoT sensors

- Condition monitoring systems

- Predictive analytics

- Machine learning algorithms

These technologies enable:

- Predictive maintenance models

- Failure probability forecasting

- Real-time equipment health monitoring

Maintenance performance metrics are evolving from static reporting tools into predictive decision systems.

Integrating Maintenance Metrics with Organizational Strategy

Maintenance does not operate in isolation. Effective organizations integrate maintenance metrics with:

- Production KPIs

- Safety metrics

- Quality indicators

- Financial performance measures

This alignment ensures maintenance contributes directly to business performance, not just technical outcomes.

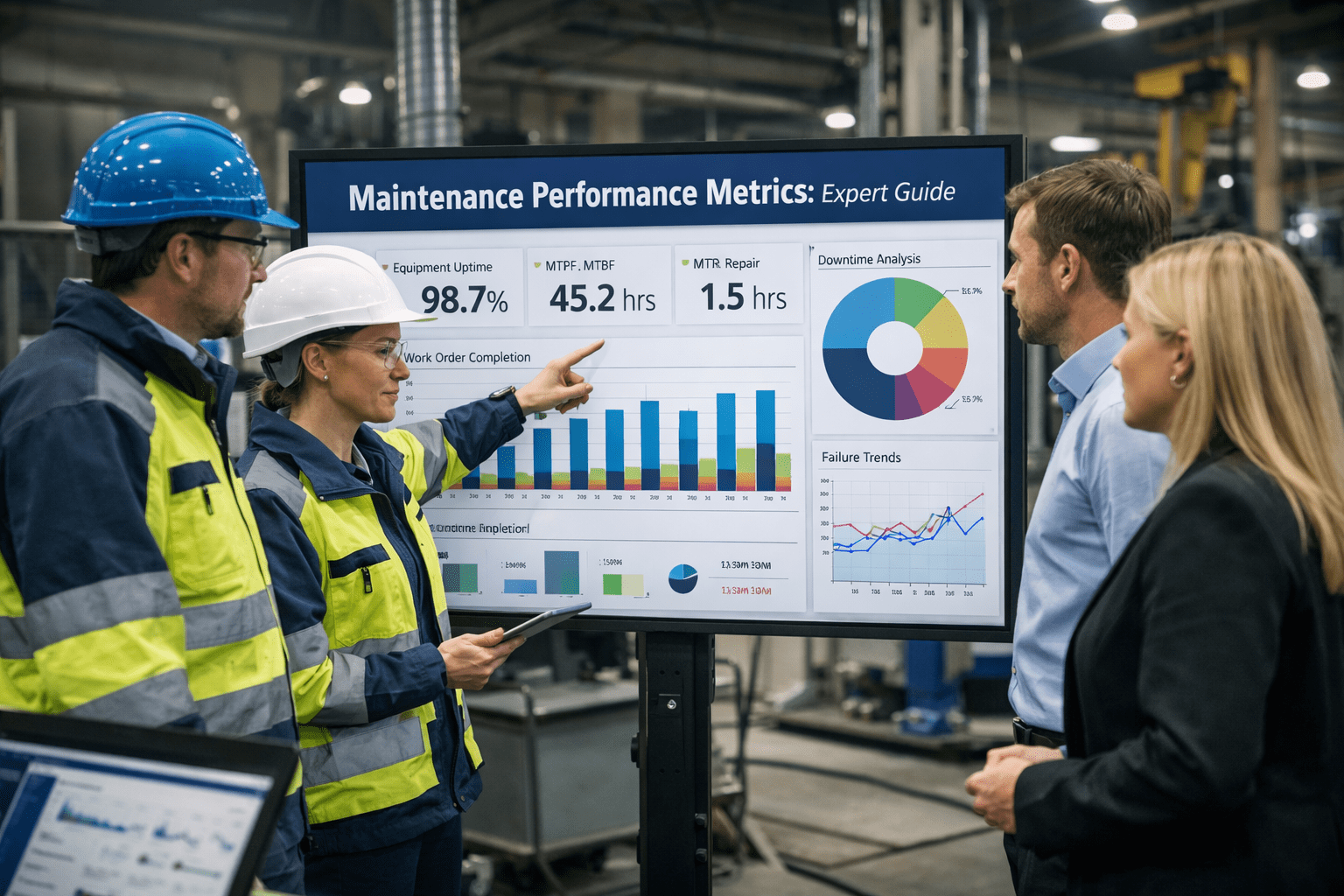

Building a Maintenance Performance Dashboard

A professional maintenance dashboard typically includes:

- Reliability metrics (MTBF, MTTR)

- PM compliance

- Downtime trends

- Cost indicators

- Workforce utilization

Dashboards should be:

- Role-based (executive vs operational views)

- Updated regularly

- Visually clear

- Action-oriented

Well-designed dashboards turn raw data into strategic insight.

Future Trends in Maintenance Performance Metrics

Maintenance performance measurement continues to evolve in several key directions:

AI-Driven Metrics

Algorithms identify hidden patterns and predict failures before symptoms appear.

Risk-Based Measurement

Metrics focus on criticality and business impact rather than volume.

Sustainability Metrics

Energy efficiency, carbon footprint, and waste reduction are increasingly included.

Experience-Based Metrics

User satisfaction and service quality become part of maintenance evaluation.

Maintenance is shifting from reactive repair to intelligent asset stewardship.

Conclusion: Why Maintenance Performance Metrics Are Essential

Maintenance performance metrics are the foundation of modern asset management. They provide organizations with the visibility, control, and insight needed to:

- Improve reliability

- Reduce downtime

- Control costs

- Enhance safety

- Extend asset lifespan

When properly designed and consistently applied, maintenance performance metrics transform maintenance from a technical necessity into a strategic business advantage.

In an environment where operational resilience and efficiency determine competitiveness, organizations that master maintenance performance measurement gain not only stronger assets—but also stronger futures.