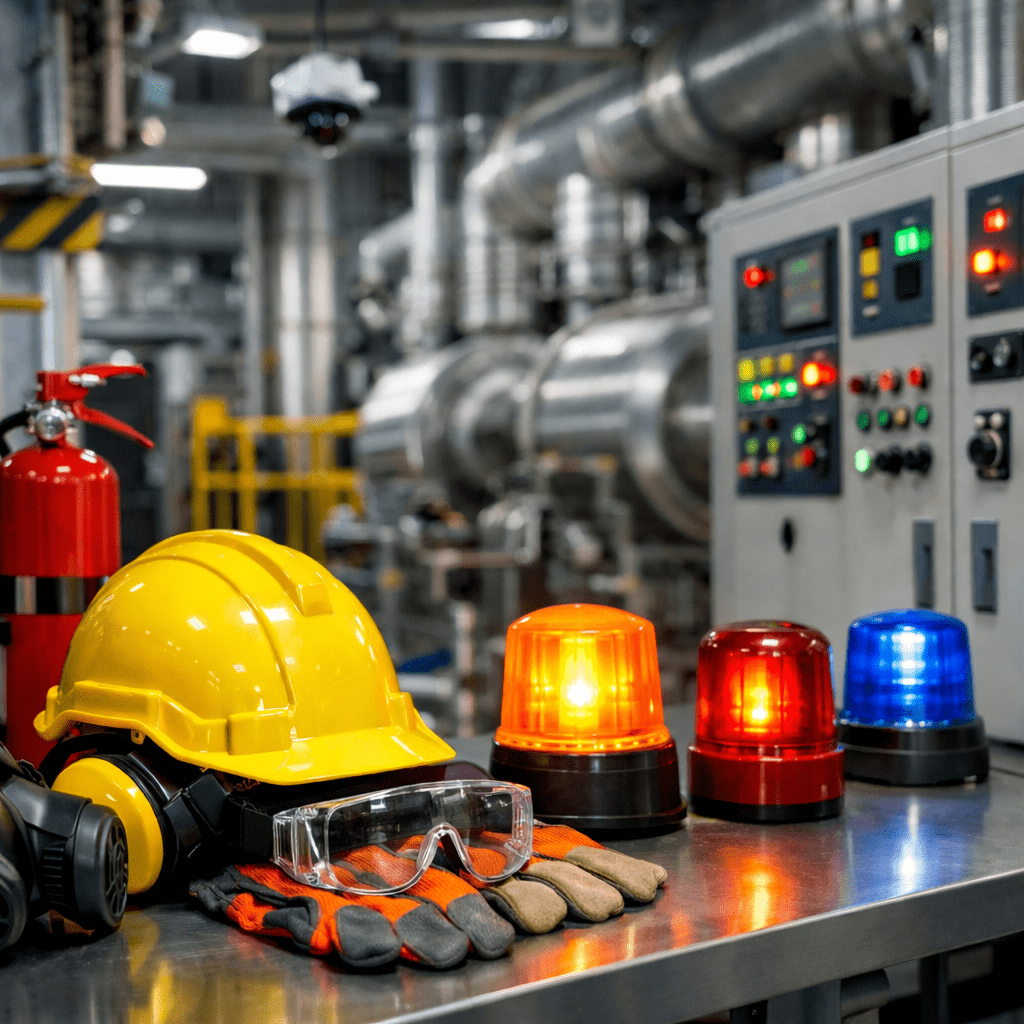

Equipment and system safety is a critical pillar of effective facilities safety management. Every facility relies on equipment, machinery, and building systems to operate efficiently. When these assets are not designed, maintained, or used correctly, they can create serious risks to people, property, and operations. For this reason, organizations must treat equipment and system safety as a core responsibility rather than a secondary task.

This article provides an expert, professional guide to equipment and system safety within the broader context of facilities safety. It is written for facilities managers, safety officers, operations leaders, and business owners who want to reduce risk, improve compliance, and maintain safe.

Understanding Equipment and System Safety

Equipment and system safety refers to the processes and controls used to ensure that machines, tools, and facility systems operate without causing harm. These systems include production equipment, electrical infrastructure, HVAC systems, fire protection, elevators, and automated controls.

In facilities safety, equipment-related incidents often result from poor maintenance, improper use, outdated systems, or lack of training. A structured approach to safety helps prevent failures before they lead to injuries or downtime.

Rather than focusing only on compliance, effective safety management emphasizes prevention, reliability, and continuous improvement.

Why Equipment and System Safety Matters?

Facilities safety depends heavily on the condition and performance of equipment and systems. When failures occur, the consequences can be severe.

Strong safety practices help organizations:

- Prevent injuries and fatalities

- Reduce equipment-related downtime

- Lower repair and replacement costs

- Maintain regulatory compliance

- Protect business continuity

In contrast, neglected systems increase the likelihood of accidents, emergency shutdowns, and costly disruptions.

Common Equipment and System Risks in Facilities

When identifying common risks, recognize that many injuries stem from unguarded machines and exposed moving parts, which OSHA’s machine guarding standards are designed to prevent and control OSHA Machine Guarding and Equipment Safety Standards.

Understanding common risks is the first step toward effective control. Equipment and system hazards vary by facility type, but several risks appear across industries.

Typical risks include:

- Mechanical failures or moving parts

- Electrical faults and exposed wiring

- Overheating equipment

- Inadequate machine guarding

- Control system malfunctions

- Poorly maintained safety interlocks

Facilities safety programs must address both visible hazards and hidden system failures that develop over time.

Safe Equipment Design and Installation

Safety begins long before equipment is put into use. Design and installation decisions directly affect long-term reliability and risk.

Facilities should ensure that:

- Equipment meets recognized safety standards

- Systems are installed by qualified professionals

- Machine guards and safety features are in place

- Emergency stops are accessible and functional

- Control panels are clearly labeled

When safety is built into design and installation, facilities reduce dependence on procedural controls alone.

Preventive Maintenance as a Safety Strategy

Preventive maintenance plays a central role in equipment and system safety. Poorly maintained systems are far more likely to fail unexpectedly.

Effective maintenance programs:

- Follow manufacturer recommendations

- Use scheduled inspections and servicing

- Address wear and deterioration early

- Document maintenance activities

By maintaining systems proactively, facilities safety teams reduce both safety risks and operational interruptions.

Inspections and Condition Monitoring

Routine inspections help identify early warning signs of failure. Facilities safety improves when inspections are structured and consistent.

Inspection activities may include:

- Visual checks for damage or leaks

- Testing safety devices and alarms

- Monitoring vibration, temperature, or noise

- Verifying electrical connections

Condition monitoring tools allow facilities to detect problems before they become dangerous, supporting safer operations.

Electrical and Energy System Safety

Electrical systems present significant risk if not properly managed. Equipment and system safety requires strict control of electrical hazards.

Key safety practices include:

- Regular electrical inspections

- Proper grounding and circuit protection

- Clear labeling of panels and disconnects

- Controlled access to electrical rooms

Facilities safety teams must ensure that only trained personnel perform electrical work and that lockout procedures are followed during maintenance.

Lockout and Control of Hazardous Energy

Unexpected energy release is a major cause of serious injuries. Controlling hazardous energy is essential for safe equipment servicing.

Facilities should:

- Establish clear lockout procedures

- Provide appropriate locking devices

- Train employees on energy isolation

- Verify zero-energy states before work begins

Strong energy control programs protect maintenance personnel and support safe system operations.

Automation and Control System Safety

Modern facilities rely heavily on automation and control systems. While automation improves efficiency, it also introduces new risks.

Facilities safety measures for automated systems include:

- Secure control logic and software

- Redundant safety interlocks

- Regular system testing

- Controlled access to programming interfaces

When automation safety is neglected, system failures can escalate rapidly and affect large areas of a facility.

Training and Authorization

Even the safest equipment can become dangerous if used incorrectly. Training is a critical component of equipment and system safety.

Effective training programs:

- Match training to specific equipment

- Include hands-on instruction

- Address normal and abnormal conditions

- Reinforce safe operating limits

Facilities should also control authorization, ensuring that only qualified personnel operate or maintain complex systems.

Incident Reporting and Investigation

Incidents and near-misses provide valuable insight into system weaknesses. Facilities safety improves when organizations learn from these events.

A strong reporting process:

- Encourages prompt reporting

- Investigates root causes

- Identifies system or process failures

- Implements corrective actions

Learning from incidents prevents repeat failures and strengthens safety performance.

Documentation and Safety Records

Documentation supports accountability and continuous improvement. Facilities safety programs should maintain accurate records related to equipment and systems.

Important records include:

- Maintenance logs

- Inspection reports

- Training records

- Incident investigations

Well-organized documentation demonstrates due diligence and supports audits and compliance efforts.

Leadership and Safety Culture

Leadership commitment is essential to equipment and system safety. When leaders prioritize safety, teams follow.

Effective leadership actions include:

- Providing resources for maintenance and upgrades

- Supporting training and inspections

- Enforcing safety rules consistently

- Encouraging reporting without fear

A strong safety culture reinforces safe behavior and proactive risk management.

Continuous Improvement in Equipment and System Safety

Facilities and technologies change over time. Therefore, safety systems must evolve as well.

Continuous improvement involves:

- Reviewing performance data

- Updating procedures and standards

- Replacing outdated equipment

- Adopting safer technologies

Facilities safety improves when organizations treat safety as an ongoing process rather than a fixed goal.

The Business Value of Safe Systems

Investing in equipment and system safety delivers measurable business benefits. Safe facilities operate more reliably and experience fewer disruptions.

Key benefits include:

- Reduced downtime

- Lower injury-related costs

- Improved employee confidence

- Enhanced organizational reputation

Safety and performance go hand in hand when systems are managed responsibly.

Conclusion: Strengthening Facilities Safety Through Equipment and System Safety

Equipment and system safety is a fundamental element of effective facilities safety. By focusing on safe design, preventive maintenance, inspections, training, and continuous improvement, organizations can significantly reduce risk.

Facilities that prioritize system reliability and safe operation protect their people, preserve assets, and support long-term success. When equipment and system safety becomes part of everyday operations, facilities move from reactive problem-solving to proactive risk control—creating safer, more resilient workplaces.