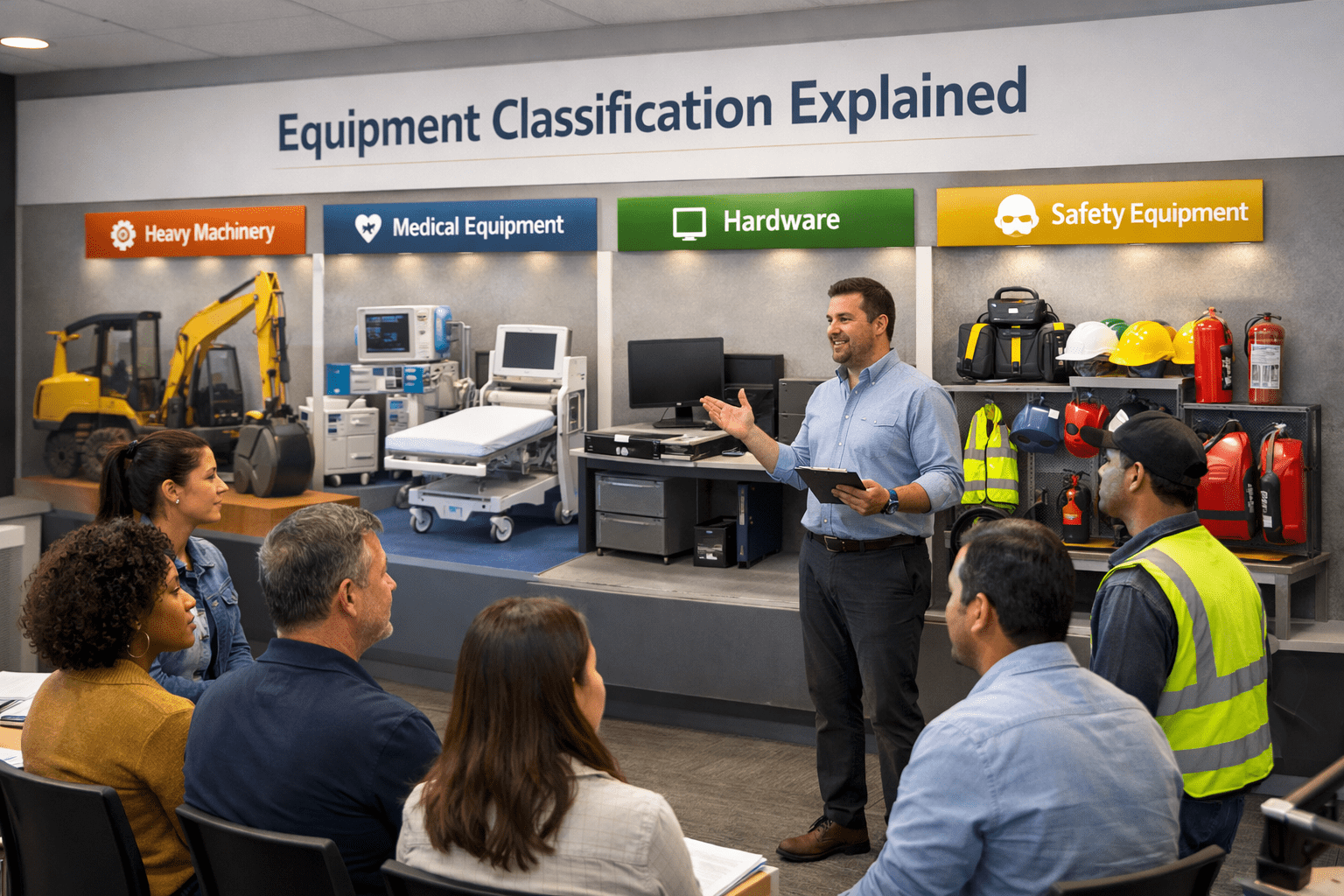

Equipment classification is a fundamental concept in asset management, facilities management, engineering, and operations. It refers to the structured process of categorizing equipment based on shared characteristics such as function, risk level, criticality, industry use, or technical complexity. When applied correctly, and improves maintenance efficiency, enhances safety, supports regulatory compliance, and enables better strategic decision-making.

In modern organizations is not just a technical exercise. Instead, it serves as a management framework that links physical assets to operational goals, financial planning, and performance measurement.

What Is Equipment Classification?

Equipment classification is the systematic grouping of physical assets into logical categories based on defined criteria such as function, risk, or operational importance, following established asset classification frameworks used in professional asset management.

Rather than treating all equipment as equal, and allows teams to understand differences in criticality, maintenance requirements, operational impact, and risk exposure. As a result, maintenance resources can be allocated more strategically.

Without proper classification, equipment inventories become disorganized. Consequently, maintenance planning becomes inefficient, compliance risks increase, and decision-making relies heavily on assumptions instead of data.

Why Equipment Classification Matters?

Playing a central role in operational excellence. More importantly, it provides the foundation for asset lifecycle management.

For example, proper classification supports:

- Improved maintenance planning

- Better risk prioritization

- Stronger regulatory compliance

- More accurate asset valuation

- Enhanced safety management

- Optimized capital investment

Therefore is not simply an administrative task. Instead, it directly affects reliability, cost control, and business continuity.

Common Equipment Classification Criteria

Organizations classify equipment using several standard criteria. Often, multiple criteria are combined to create a comprehensive classification structure.

Functional Classification

Functional classification groups equipment based on what it does.

For instance:

- Production equipment

- Utility systems

- Safety systems

- Support equipment

This approach helps organizations understand operational dependencies and system relationships.

Criticality Classification

Criticality classification evaluates the importance of equipment to operations.

Typically, equipment is classified as:

- Critical

- Essential

- Non-critical

Critical equipment directly impacts safety, production, or regulatory compliance. Therefore, it usually receives higher maintenance priority.

Risk-Based Classification

Risk-based classification considers the probability and consequences of equipment failure.

In this model, equipment is evaluated based on:

- Likelihood of failure

- Impact on safety

- Environmental consequences

- Financial losses

As a result, high-risk equipment receives stricter inspection and monitoring.

Technical Complexity Classification

Technical classification groups equipment based on complexity and skill requirements.

For example:

- Basic equipment

- Intermediate systems

- Advanced or specialized systems

This approach supports workforce planning and training strategies.

Industry-Based Equipment Classification

Different industries applies in specialized ways.

Manufacturing Equipment

In manufacturing, equipment is commonly classified as:

- Process equipment

- Packaging equipment

- Material handling systems

- Quality control equipment

This structure aligns maintenance planning with production workflows.

Facilities and Building Systems

In facilities management, classification often includes:

- HVAC systems

- Electrical systems

- Plumbing systems

- Fire protection systems

- Security systems

This classification supports compliance and safety management.

Healthcare Equipment

Healthcare organizations classify equipment by:

- Life-support equipment

- Diagnostic devices

- Monitoring systems

- Non-clinical equipment

This approach ensures patient safety and regulatory compliance.

Equipment Classification by Asset Lifecycle

It also evolves across the asset lifecycle.

New Assets

New equipment is classified during procurement. At this stage, classification focuses on:

- Functional role

- Warranty coverage

- Vendor support

- Regulatory requirements

This early classification ensures accurate asset registration.

Operational Assets

During operation, It supports:

- Maintenance scheduling

- Spare parts management

- Performance tracking

As a result, operational classification becomes the basis for CMMS structures.

End-of-Life Assets

At the end of life, classification supports:

- Replacement planning

- Decommissioning

- Disposal compliance

Therefore, lifecycle-based classification improves long-term sustainability.

Equipment Classification in Maintenance Management

One of the most practical applications is maintenance management.

Preventive Maintenance

Classification helps determine maintenance frequency. For example, critical equipment may require weekly inspections, while non-critical equipment may only require quarterly checks.

Predictive Maintenance

In predictive maintenance, classification identifies which equipment benefits most from condition monitoring.

High-risk and high-cost assets typically receive:

- Sensors

- Vibration analysis

- Thermal imaging

Spare Parts Optimization

Classification also improves inventory management. By linking spare parts to equipment classes, organizations reduce stockouts and overstocking.

Digital Systems and Equipment Classification

Modern asset systems rely heavily on classification structures.

CMMS and EAM Systems

Computerized Maintenance Management Systems use classification to organize:

- Asset hierarchies

- Maintenance plans

- Failure codes

- Performance reports

Without consistent classification, digital systems become unreliable and fragmented.

Data Analytics and Reporting

Enabling meaningful analytics. Instead of analyzing individual assets, organizations can analyze entire equipment categories.

This supports:

- Failure trend analysis

- Cost benchmarking

- Performance comparison

Best Practices for Equipment Classification

To implement effectively and organizing should follow structured best practices.

Standardize Classification Rules

Use consistent definitions across departments to avoid confusion.

Involve Technical Experts

Classification should be validated by engineers and maintenance professionals.

Align with Business Objectives

Classification should reflect operational priorities, not just technical details.

Review Regularly

As operations evolve, classification structures should be updated.

Integrate with Digital Systems

Classification must align with CMMS, ERP, and asset management platforms.

Common Challenges in Equipment Classification

Despite its benefits and often faces challenges.

Inconsistent Terminology

Different teams may use different names for the same equipment.

Over-Complex Structures

Excessive categories create confusion and slow decision-making.

Poor Data Quality

Incomplete asset data undermines classification accuracy.

Lack of Governance

Without ownership, classification systems quickly deteriorate.

Therefore, successful classification requires governance, training, and leadership support.

The Strategic Value of Equipment Classification

Transforming asset management from reactive maintenance into strategic planning.

Organizations with strong classification systems benefit from:

- Higher asset reliability

- Lower maintenance costs

- Better safety outcomes

- Improved regulatory compliance

- Stronger financial forecasting

As a result, classification becomes a competitive advantage rather than a technical formality.

Equipment Classification and Organizational Maturity

IT also reflects organizational maturity.

Low-maturity organizations rely on informal lists and spreadsheets. In contrast, high-maturity organizations use structured classification linked to digital platforms and performance metrics.

Therefore, improving classification is often one of the fastest ways to raise overall maintenance maturity.

Conclusion

Equipment classification is a foundational concept in professional asset and maintenance management. By grouping equipment based on function, risk, criticality, and technical complexity, organizations gain clearer insight into operational priorities.

From maintenance planning and compliance to analytics and strategic investment, equipment classification supports every stage of the asset lifecycle.

In today’s data-driven environment, equipment classification is no longer optional. Instead, it is a strategic requirement for operational excellence, financial sustainability, and long-term business resilience.