Maintenance documentation types play a fundamental role in modern asset management across industries such as facilities management, manufacturing, healthcare, transportation, and utilities. In particular, these documents do not merely record maintenance activities; instead, they provide structured systems for improving reliability, ensuring compliance, and supporting data-driven decision-making.

As a result, organizations that invest in strong documentation practices consistently achieve lower downtime, improved safety, and longer asset life. Moreover, effective documentation enables maintenance teams to move from reactive problem-solving to proactive and predictive strategies.

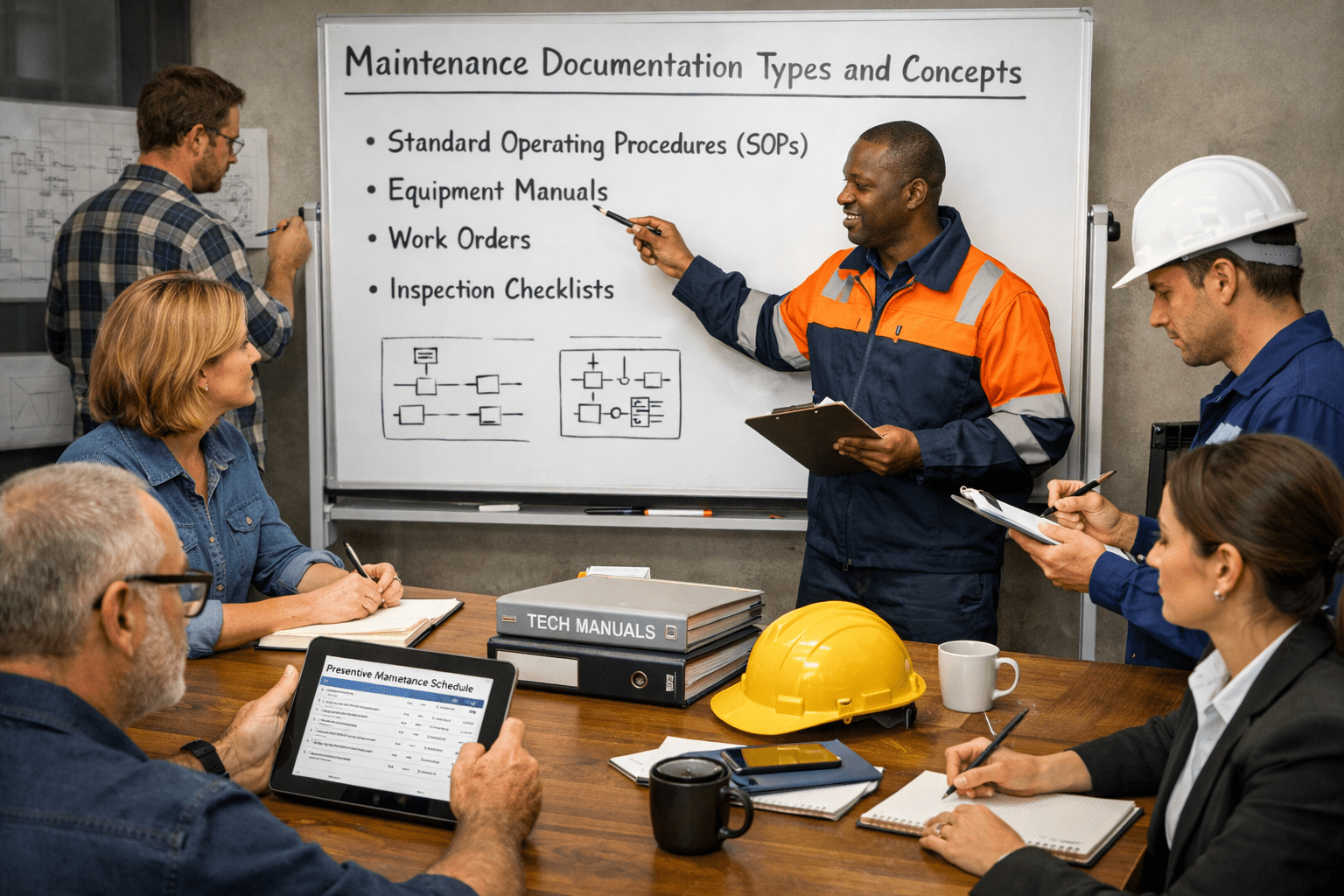

What Are Maintenance Documentation Types?

Maintenance documentation types refer to the standardized records used to capture, organize, and analyze information related to maintenance operations. These records include technical manuals, work orders, inspection checklists, and performance reports, as outlined in a professional guide to maintenance documentation by SafetyCulture.

Rather than functioning as simple logs, maintenance documents act as operational intelligence tools. For example, through consistent documentation, organizations gain visibility into system performance and can identify patterns that would otherwise remain hidden.

Without proper documentation, maintenance becomes fragmented. Consequently, teams rely on informal communication, which increases the likelihood of errors, downtime, and safety incidents.

Why Maintenance Documentation Matters?

Maintenance documentation is critical because it supports both operational continuity and strategic performance. In practice, documentation provides the foundation for maintenance planning, compliance audits, and financial forecasting.

For instance, maintenance documentation enables:

- Improved equipment reliability

- Stronger regulatory compliance

- Better safety management

- More accurate budget planning

- Easier knowledge transfer

- Continuous improvement

Therefore, documentation quality should be treated as a strategic investment rather than an administrative burden.

Core Maintenance Documentation Types

Several core maintenance documentation types are used across professional maintenance systems. Together, they form a complete picture of asset performance and operational health.

Work Orders

Work orders are formal instructions that authorize maintenance tasks. Specifically, they define what needs to be done, where it will occur, who is responsible, and when it must be completed.

Typically, work orders include:

- Asset identification

- Task description

- Priority level

- Assigned personnel

- Materials required

- Completion notes

As a result, work orders create accountability and enable traceability for every maintenance action.

Preventive Maintenance Schedules

Preventive maintenance schedules outline planned maintenance activities based on time intervals or usage levels. In contrast to reactive approaches, preventive schedules focus on preventing failures before they occur.

Consequently, organizations that follow preventive schedules experience:

- Reduced unexpected breakdowns

- Lower repair costs

- Improved asset lifespan

- Enhanced safety performance

Therefore, preventive documentation shifts maintenance from crisis management to performance management.

Inspection Checklists

Inspection checklists standardize the evaluation of asset conditions. In addition, they guide technicians through predefined steps and ensure consistent assessments.

Furthermore, inspection checklists help:

- Detect early signs of failure

- Reduce human error

- Improve data quality

- Support compliance programs

As such, checklists remain one of the most reliable and cost-effective documentation tools.

Asset Registers

An asset register is a centralized inventory of all physical assets. Essentially, it provides critical information for lifecycle management.

Typically, asset registers include:

- Asset identification

- Location and department

- Manufacturer and model

- Installation date

- Warranty information

- Maintenance history

Therefore, asset registers support strategic planning, capital budgeting, and risk analysis.

Maintenance Logs

Maintenance logs record all maintenance activities over time. In effect, they create a continuous historical record of asset behavior.

Moreover, maintenance logs capture:

- Service dates

- Maintenance type

- Technician observations

- Parts replaced

- Downtime impact

As a result, maintenance logs support root cause analysis and performance optimization.

Compliance and Safety Documentation

In regulated environments, certain maintenance documentation types are legally required. Accordingly, these records demonstrate compliance with safety and regulatory standards.

Safety Records

Safety records document inspections, incident reports, and corrective actions. In addition, they support workplace safety programs and hazard mitigation.

Furthermore, safety documentation:

- Reduces legal risk

- Improves training quality

- Strengthens accountability

Therefore, safety records are essential for sustainable operations.

Regulatory Compliance Reports

Regulatory compliance reports verify adherence to external standards. For example, they may include:

- Electrical inspection certificates

- Fire system testing logs

- Environmental compliance records

- Equipment certification reports

Consequently, these documents are critical for passing audits and maintaining operating licenses.

Planning and Strategic Documentation

Beyond daily operations, maintenance documentation supports long-term planning. In this context, strategic documents guide resource allocation and performance improvement.

Maintenance Plans

Maintenance plans define how assets will be managed over time. Specifically, they outline strategies, priorities, and objectives.

As a result, maintenance plans:

- Align maintenance with business goals

- Support risk-based decision-making

- Improve resource efficiency

Therefore, planning documentation transforms maintenance into a management function.

Lifecycle Cost Reports

Lifecycle cost reports analyze the total cost of asset ownership. In other words, they evaluate acquisition, operation, maintenance, and disposal costs.

Consequently, these reports help organizations:

- Optimize replacement timing

- Reduce total operating costs

- Improve investment decisions

Digital Maintenance Documentation Types

With technological advancement, maintenance documentation increasingly becomes digital. As a result, organizations gain better visibility and control.

CMMS Records

CMMS platforms centralize maintenance data. In particular, they store work orders, asset histories, inventory data, and performance metrics.

Therefore, CMMS systems:

- Improve coordination

- Reduce data loss

- Enable advanced reporting

Digital Inspection Forms

Digital inspection forms replace paper-based documentation. Furthermore, they enable real-time updates and automated reporting.

In addition, digital forms:

- Improve efficiency

- Reduce administrative effort

- Enhance data accuracy

Predictive Maintenance Reports

Predictive reports use sensor data and analytics. In effect, they forecast failures before they occur.

Consequently, organizations can:

- Schedule maintenance optimally

- Reduce unplanned downtime

- Extend asset life

Best Practices for Maintenance Documentation

To maximize documentation effectiveness, organizations should follow best practices. First, standardize templates across systems. Second, train staff thoroughly. Third, audit documentation regularly. Fourth, integrate systems wherever possible. Finally, analyze data trends to drive continuous improvement.

Common Challenges in Maintenance Documentation

Despite its value, documentation faces challenges. For example, incomplete records reduce insight. Similarly, inconsistent terminology creates confusion. Moreover, manual processes increase error rates.

Therefore, successful documentation programs require strong leadership, training, and digital tools.

The Strategic Value of Maintenance Documentation

High-quality maintenance documentation transforms maintenance into a strategic capability. As a result, organizations achieve improved reliability, reduced risk, and enhanced decision-making.

Ultimately, documentation becomes a source of organizational intelligence rather than a compliance exercise.

Conclusion

Maintenance documentation types are essential for professional asset management. From work orders and inspection checklists to digital CMMS records and predictive reports, each document contributes to operational excellence.

Therefore, organizations that invest in standardized, digital, and data-driven documentation practices gain a sustainable competitive advantage.