E-commerce continues to grow at an unprecedented rate. Behind every “Buy Now” click is a complex system of physical operations working to move products from suppliers to warehouses and ultimately to customers. At the heart of these physical operations lies one essential discipline: material handling basics.

For beginners entering the world of logistics, warehouse management, or online retail operations, understanding and It is crucial. It determines how efficiently products flow, how safely employees work, and how satisfied customers remain.

In this comprehensive guide, we’ll break down material handling fundamentals in a beginner-friendly yet technical way to help you build a strong operational foundation.

What Are Material Handling Basics in E-Commerce?

It refer to the systematic movement, storage, protection, and control of goods throughout the e-commerce fulfillment process.

In simple terms, material handling is how products:

- Move from receiving docks to storage areas

- Get picked and packed

- Travel through sorting systems

- Ship to customers

Efficient material handling reduces costs, prevents product damage, improves order accuracy, and enhances overall operational performance.

Why Material Handling Basics Matter in Physical Operations?

Efficient order fulfillment depends on proper materials handling in e-commerce operations, ensuring goods move safely from receiving to shipping without delays or damage. Physical operations in e-commerce include:

- Receiving inventory

- Warehousing

- Inventory management

- Order picking

- Packing

- Shipping

- Returns processing

Every one of these processes depends on proper material handling practices.

When ignored, businesses experience:

- Slow order fulfillment

- Increased labor costs

- Higher return rates due to damage

- Workplace injuries

- Inventory inaccuracies

On the other hand, mastering leads to scalable, efficient, and profitable operations.

Core Principles of Material Handling Basics

Understanding the principles behind material handling basics helps create systems that are safe and cost-effective.

1. Planning Principle

All material movement should be planned. Random workflows cause congestion and delays. Warehouse layout, equipment selection, and storage systems must align with order volume and SKU variety.

2. Standardization Principle

Standard processes reduce errors. For example:

- Standard bin sizes

- Standard pallet configurations

- Standard labeling procedures

Standardization improves efficiency and simplifies training.

3. Work Minimization Principle

The fewer times a product is touched, the lower the cost. Reducing unnecessary movement is one of the most important material handling basics.

4. Ergonomic Principle

Safety matters. Equipment and workflows should reduce strain on workers. Proper lifting techniques and ergonomic workstations prevent injuries.

5. Automation Principle

As order volume grows, automation becomes essential. Conveyor systems, barcode scanners, and robotics improve speed and accuracy.

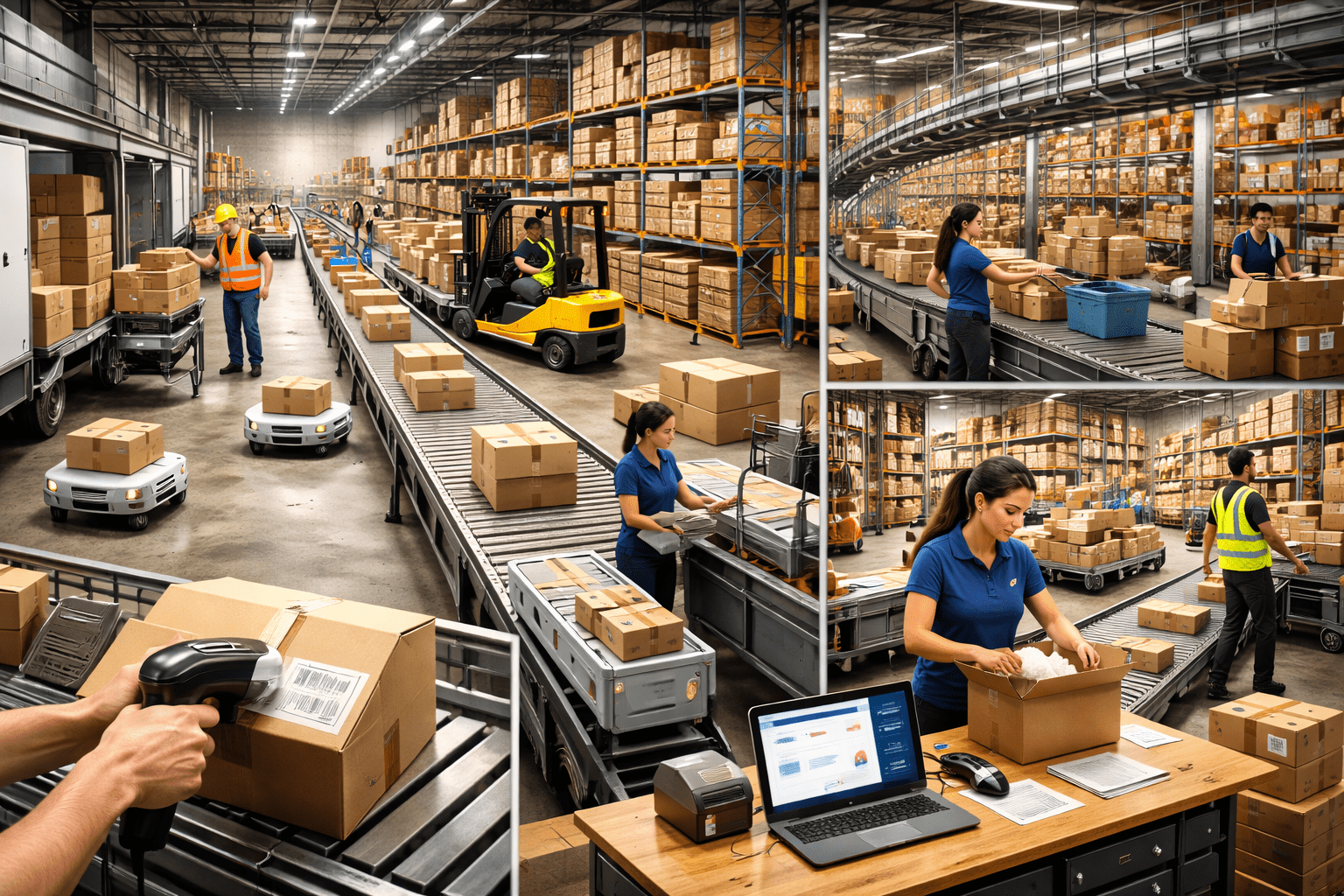

Types of Material Handling Systems in E-Commerce

Material handling systems fall into three main categories.

1. Manual Material Handling

Manual handling involves human labor using tools like:

- Hand trucks

- Pallet jacks

- Shelving systems

- Picking carts

This approach works for small or startup e-commerce businesses. However, it may not scale efficiently for high-volume operations.

2. Semi-Automated Systems

These systems combine human labor with equipment such as:

- Conveyor belts

- Sortation systems

- Barcode scanners

- Warehouse Management Systems (WMS)

Semi-automation improves productivity while maintaining flexibility.

3. Fully Automated Systems

Large e-commerce fulfillment centers use advanced solutions like:

- Automated Storage and Retrieval Systems (AS/RS)

- Robotics-assisted picking

- Automated guided vehicles (AGVs)

- High-speed sorters

These systems maximize efficiency but require significant capital investment.

Key Equipment in Material Handling Basics

Choosing the right equipment is essential for efficient physical operations.

Storage Equipment

- Pallet racks

- Shelving systems

- Mezzanine floors

- Bin storage

These systems maximize vertical space and improve organization.

Transport Equipment

- Forklifts

- Conveyor belts

- AGVs

- Pallet jacks

Transport equipment moves goods between zones quickly and safely.

Unit Load Formation Equipment

- Pallets

- Containers

- Totes

- Shrink wrapping machines

Unit loads reduce the number of trips needed to move goods.

The Role of Warehouse Layout in Material Handling Basics

Warehouse layout directly impacts material flow.

Common layout types include:

U-Shaped Layout

Receiving and shipping are located close together. This design minimizes travel distance and improves efficiency.

I-Shaped Layout

Goods move in a straight line from receiving to shipping. Ideal for high-volume operations.

L-Shaped Layout

Suitable for buildings with space constraints.

An optimized layout supports material handling basics by reducing congestion and improving product flow.

Material Handling in the Order Fulfillment Process

Understanding where material handling basics apply in daily operations is important.

1. Receiving

When inventory arrives:

- Products are unloaded

- Inspected

- Scanned into inventory

- Stored

Proper material handling prevents damage during unloading.

2. Storage

Products are placed in designated locations using optimized slotting strategies. High-demand items are stored closer to picking areas.

3. Picking

Order picking is labor-intensive. Methods include:

- Single-order picking

- Batch picking

- Zone picking

- Wave picking

Efficient material handling reduces travel time and improves picking speed.

4. Packing

Items are securely packed using:

- Protective materials

- Right-sized boxes

- Automated packing stations

Good material handling minimizes product damage during shipment.

5. Shipping

Orders are sorted and staged for carrier pickup. Conveyor systems and scanning stations improve accuracy.

Safety Considerations in Material Handling Basics

Safety is a critical component of physical operations.

Common risks include:

- Back injuries from improper lifting

- Collisions with forklifts

- Slips and falls

- Falling objects from racks

Best practices include:

- Regular safety training

- Clear aisle markings

- Equipment maintenance

- Personal protective equipment (PPE)

Safe material handling reduces downtime and compensation claims.

Cost Impact of Material Handling Basics

Material handling accounts for a significant portion of warehouse operating costs.

Costs include:

- Labor

- Equipment

- Maintenance

- Energy consumption

- Space utilization

Improving material handling basics can:

- Reduce labor hours

- Lower damage rates

- Increase throughput

- Improve customer satisfaction

Even small workflow improvements can result in major cost savings over time.

Technology Supporting Material Handling Basics

Modern e-commerce relies heavily on technology.

Warehouse Management Systems (WMS)

A WMS tracks inventory movement and optimizes picking routes.

Barcode and RFID Systems

These technologies improve inventory accuracy and reduce human error.

Robotics and Automation

Robotic picking systems and AGVs streamline repetitive tasks.

Technology enhances material handling basics by improving visibility and efficiency.

Scalability and Future Growth

As e-commerce businesses grow, material handling systems must scale.

Scalability strategies include:

- Modular racking systems

- Expandable conveyor networks

- Cloud-based WMS platforms

- Flexible labor planning

Planning for growth ensures that physical operations can handle seasonal peaks and increased order volume.

Common Mistakes in Material Handling Basics

Beginners often make these mistakes:

- Overcrowded storage areas

- Poor SKU organization

- Ignoring data analysis

- Delaying automation too long

- Underestimating safety requirements

Avoiding these mistakes improves operational stability.

Final Thoughts on Material Handling Basics

Material handling basics are the backbone of physical operations in e-commerce. From receiving inventory to shipping orders, every step depends on efficient movement and storage of goods.

For beginners, focusing on:

- Smart warehouse layout

- Proper equipment selection

- Standardized processes

- Safety measures

- Scalable technology

will create a strong operational foundation.

As your e-commerce business grows, refining material handling basics will help reduce costs, improve speed, and enhance customer satisfaction.

In today’s competitive market, physical operations are not just about moving boxes — they are about building systems that deliver accuracy, efficiency, and long-term success.

Master the material handling basics, and you master the engine that powers e-commerce fulfillment.