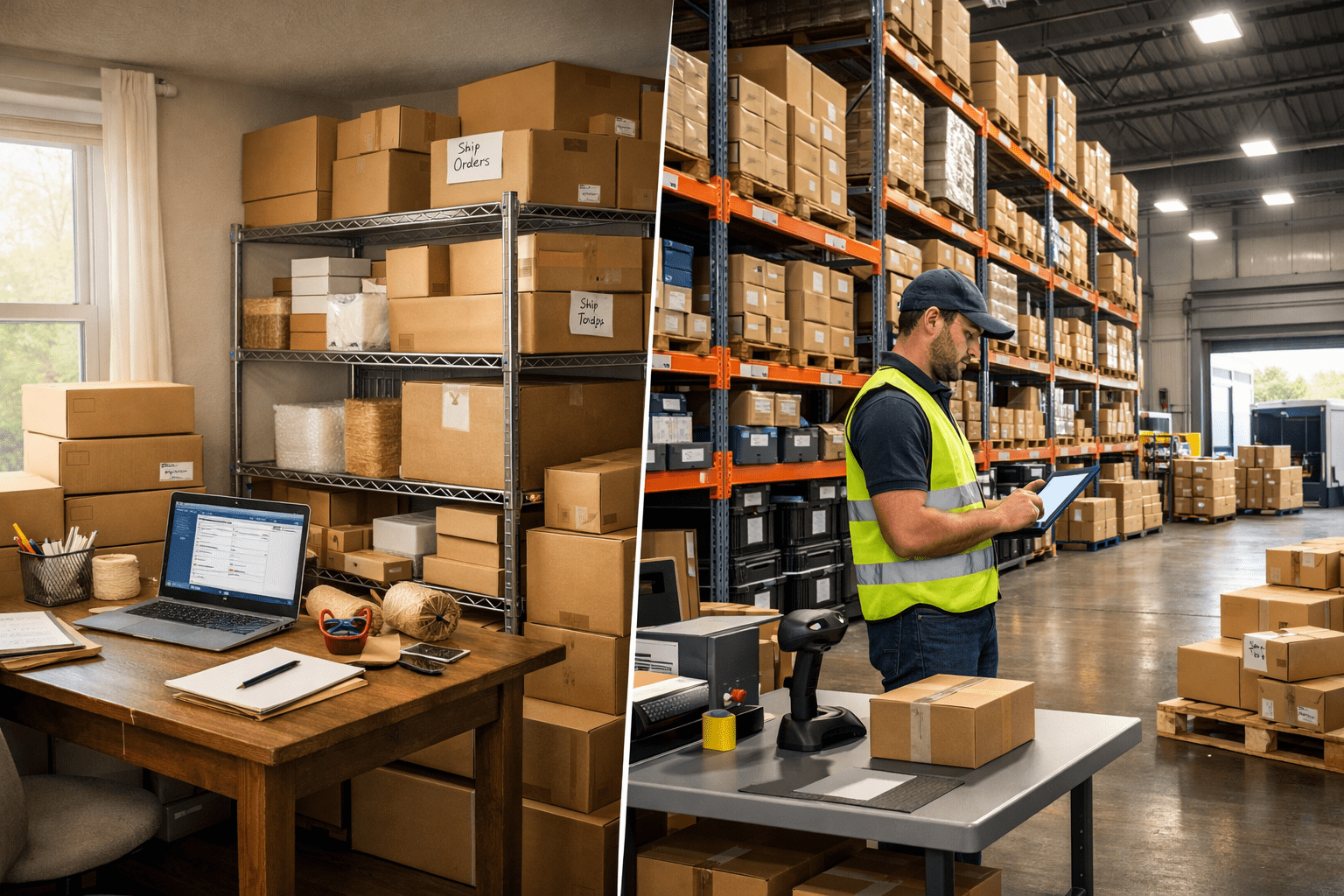

Transitioning from home to warehouse is a major milestone for growing businesses that sell physical products. What begins as packing orders in a spare bedroom or garage can quickly evolve into a need for structured storage, faster fulfillment, and scalable systems. As order volume increases, moving into a warehouse becomes less about space and more about operational efficiency and long-term growth.

If you are transitioning from home to warehouse, you are not just changing locations. You are upgrading your entire operational system.

This guide will walk you through the process step by step in a beginner-friendly yet expert-level way, helping you avoid common mistakes and scale confidently.

Why Businesses Outgrow Home Operations?

Many entrepreneurs start from home because it is affordable and flexible. However, growth introduces new operational challenges:

- Limited storage space

- Slower order fulfillment

- Inventory disorganization

- Increased shipping costs

- Carrier pickup restrictions

- Safety and zoning concerns

- Difficulty hiring staff

When daily order volume consistently strains your available space and time, it is a clear signal that scaling physical commerce operations requires a more structured environment.

Moving into a warehouse is not about prestige. It is about efficiency, scalability, and sustainability.

Signs You Are Ready for a Warehouse

Before committing to a lease, confirm that your business is operationally prepared.

You may be ready if:

- You process 20–50+ orders daily consistently

- Inventory occupies multiple rooms or off-site storage

- Shipping carriers struggle with residential pickups

- You cannot restock or pack orders efficiently

- You plan to hire team members

- Revenue supports long-term rent and utilities

If your operations feel reactive rather than organized, the transition may help you regain control.

Step 1: Financial Planning Before the Move

The biggest mistake in transitioning from home to warehouse is underestimating costs.

Beyond rent, consider:

- Security deposit

- Shelving and racking systems

- Pallet jacks or forklifts

- Warehouse insurance

- Utilities (electricity, internet, water)

- Security systems

- Workstations and packing tables

- Waste disposal and recycling

- Signage and permits

Create a six-month financial buffer before signing a lease. A warehouse should reduce stress — not create new financial pressure.

Step 2: Choosing the Right Warehouse Size

Bigger is not always better.

Select a space based on:

- Current inventory volume

- Projected 12-month growth

- Ceiling height (vertical storage matters)

- Loading dock or ground-level access

- Parking availability

- Proximity to shipping carriers

- Accessibility for employees

A common beginner error is leasing too much space and struggling to cover rent. Instead, choose a space that supports growth while maintaining healthy cash flow.

Step 3: Designing Efficient Warehouse Layout

Scaling physical commerce operations requires workflow optimization.

An effective warehouse layout includes:

- Receiving Area

- Inventory Storage Zone

- Picking Area

- Packing Stations

- Shipping Staging Area

- Returns Processing Section

Design the layout to minimize walking distance and reduce handling time. Every extra step costs labor hours.

Use clear labeling systems and barcode scanning early. Implementing structure now prevents chaos later.

Step 4: Upgrading Inventory Management Systems

Home-based operations often rely on spreadsheets. That method rarely works at warehouse scale. As order volume increases, understanding ecommerce warehousing becomes essential. Reviewing ecommerce warehousing best practices can help you compare in-house storage with third-party fulfillment solutions and determine which model supports long-term growth.

Consider implementing:

- Inventory management software

- Barcode scanners

- SKU standardization

- Batch tracking (if applicable)

- Automated stock alerts

- Integrated shipping platforms

Accurate inventory tracking reduces overselling, prevents stockouts, and improves customer trust.

This is a crucial step when transitioning from home to warehouse because manual processes become bottlenecks at scale.

Step 5: Improving Shipping and Fulfillment Efficiency

Warehouse operations allow you to:

- Negotiate better carrier rates

- Schedule daily pickups

- Use bulk packaging supplies

- Implement standardized packing procedures

- Reduce order processing time

Establish clear fulfillment SOPs (Standard Operating Procedures):

- Order picking process

- Quality control checks

- Packaging guidelines

- Label printing workflow

- Carrier handoff procedures

Consistency improves speed and reduces costly shipping errors.

Step 6: Hiring and Team Management

A warehouse environment often means hiring help.

Start with:

- Warehouse associate

- Inventory coordinator

- Fulfillment specialist

Create documented processes before hiring. Otherwise, you will train inconsistently and experience inefficiency.

Invest in:

- Clear job descriptions

- Safety training

- Performance metrics

- Accountability systems

Scaling physical commerce operations means building systems that function beyond the founder’s direct involvement.

Step 7: Legal and Compliance Considerations

Operating commercially requires compliance with:

- Zoning regulations

- Fire safety standards

- Insurance coverage

- Labor laws

- Occupational safety rules

Consult local authorities or a small business advisor to ensure your warehouse setup meets regulations.

Failure to address compliance early can result in fines or shutdowns.

Step 8: Technology Integration for Long-Term Growth

As you expand, technology becomes a competitive advantage.

Consider:

- Warehouse Management Systems (WMS)

- Integrated ERP software

- Automated label printers

- Inventory forecasting tools

- Cloud-based accounting systems

These tools help maintain visibility across purchasing, stock levels, and order fulfillment.

Technology ensures that transitioning from home to warehouse becomes a scalable upgrade — not just a physical move.

Common Mistakes to Avoid

Even experienced entrepreneurs make errors during expansion.

Avoid these pitfalls:

- Moving too early without consistent order volume

- Underestimating storage layout planning

- Ignoring workflow efficiency

- Over-hiring too quickly

- Neglecting cost tracking

- Failing to secure proper insurance

- Keeping informal processes

Structure is your biggest asset at this stage.

How a Warehouse Changes Your Business Mindset?

The shift from home-based operations to warehouse management is psychological as much as operational.

At home, tasks are informal. In a warehouse:

- Systems matter

- Documentation matters

- Accountability matters

- Efficiency directly impacts profitability

You transition from “doing everything yourself” to “managing systems and people.”

This mindset shift is essential for sustainable scaling.

Measuring Success After the Move

Once you are operating in a warehouse, track performance metrics such as:

- Order processing time

- Fulfillment accuracy rate

- Inventory turnover

- Shipping cost per order

- Labor cost per unit

- Return processing time

If metrics improve and stress decreases, your scaling decision was strategic.

Is Third-Party Fulfillment an Alternative?

Some businesses consider 3PL (third-party logistics) instead of leasing a warehouse.

Pros of 3PL:

- No lease commitment

- Lower upfront cost

- Immediate logistics expertise

Cons:

- Less operational control

- Per-order fulfillment fees

- Storage charges

Evaluate your brand needs carefully. If customization, branding, and hands-on quality control are important, managing your own warehouse may be the better choice.

Long-Term Strategic Benefits

Transitioning from home to warehouse offers significant advantages:

- Increased operational efficiency

- Better inventory control

- Improved shipping rates

- Professional brand credibility

- Scalability for wholesale and B2B expansion

- Easier staff onboarding

- Enhanced growth forecasting

It transforms your business from a startup hustle into a structured operation.

Final Thoughts on Scaling Physical Commerce Operations

Scaling physical commerce operations is a pivotal step in business growth. The decision to move from a home setup to a warehouse environment signals maturity, ambition, and long-term planning.

However, the move must be strategic — not emotional.

When transitioning from home to warehouse, focus on:

- Financial readiness

- Workflow design

- Inventory accuracy

- Shipping efficiency

- Team structure

- Compliance and safety

Growth is not just about more orders. It is about building systems that can handle more orders without breaking.

If planned carefully, your warehouse becomes more than storage space. It becomes the foundation for sustainable, scalable success.

And that is what real operational growth looks like.