Effective lighting is a cornerstone of safe and productive worksites and facilities. Whether in manufacturing plants, construction sites, warehouses, or commercial facilities, proper lighting not only ensures operational efficiency but also reduces risks, supports compliance with safety regulations, and enhances overall employee well-being. Understanding worksite and facility lighting fundamentals is essential for managers, engineers, and safety professionals aiming to optimize visibility and operational performance.

The Importance of Lighting in Worksites and Facilities

Lighting is more than just illumination. On a functional level, it directly affects the visibility of workspaces, equipment, and pathways, which impacts productivity and safety. Poor lighting can lead to errors, accidents, and fatigue, while well-planned lighting improves accuracy, alertness, and morale.

According to occupational safety studies, inadequate lighting contributes to a significant percentage of workplace accidents, particularly in high-risk industries such as construction, manufacturing, and logistics. This underscores the necessity of implementing effective lighting and visibility systems that adhere to both operational and safety standards.

Key Principles of Worksite and Facility Lighting Fundamentals

1. Adequate Illumination Levels

The first principle of worksite lighting fundamentals is ensuring appropriate illumination levels for the tasks being performed. Measured in lux or foot-candles, illumination levels vary depending on the type of activity:

- High-precision tasks: Activities like assembly or quality control require higher illumination, typically 500–1,000 lux.

- General facility areas: Warehouses, corridors, and storage spaces usually need 100–300 lux.

- Safety zones and emergency pathways: Even lower levels, around 50–100 lux, may suffice, but visibility must remain clear.

Regular audits and lighting measurements are crucial to maintain consistent illumination across all work areas.

2. Uniformity and Reduced Glare

Uneven lighting or glare can compromise visibility and cause eye strain. The fundamentals of facility lighting emphasize uniform light distribution to minimize shadows, dark spots, and reflective glare. Strategies include:

- Using diffused or indirect lighting to reduce harsh contrasts.

- Positioning light fixtures strategically to cover work zones comprehensively.

- Employing anti-glare shielding, especially in areas with reflective surfaces.

Maintaining uniformity ensures that employees can focus on tasks without visual discomfort, ultimately improving productivity.

3. Color Rendering and Visual Accuracy

Color rendering index (CRI) is a critical consideration in worksite lighting systems. A high CRI ensures that colors are perceived accurately, which is essential in tasks like inspection, quality control, or any activity requiring color differentiation. Facilities with low-CRI lighting risk misidentification of materials, defects, or safety hazards.

4. Energy Efficiency and Sustainability

Modern lighting solutions must balance visibility requirements with energy efficiency. LED lighting has become the industry standard due to its low energy consumption, long lifespan, and adaptability. Facility managers should consider:

- Motion sensors and timers for areas with intermittent occupancy.

- Daylight harvesting in spaces with windows or skylights.

- High-efficiency fixtures designed for specific tasks and zones.

Efficient lighting reduces operational costs while supporting environmental sustainability goals.

5. Safety Compliance and Standards

Worksite lighting must meet regulatory standards such as OSHA, ANSI, or ISO norms. These standards define minimum illumination levels, emergency lighting requirements, and signage visibility. Compliance ensures legal protection, worker safety, and operational reliability.

Key safety considerations include:

- Emergency lighting: Backup systems must provide adequate illumination during power outages.

- Exit and pathway marking: Clearly lit egress routes reduce evacuation time in emergencies.

- Hazard zone illumination: Areas near machinery, chemicals, or moving equipment require dedicated lighting.

6. Maintenance and Longevity

Lighting is only effective if maintained properly. Facility lighting fundamentals include proactive maintenance programs that monitor fixture performance, replace aging bulbs, and clean reflective surfaces. Neglecting maintenance can result in reduced illumination, increased energy costs, and safety risks.

Types of Lighting Systems for Worksites and Facilities

Understanding the different types of lighting systems helps optimize worksite visibility:

1. Ambient Lighting

Ambient lighting provides general illumination for overall facility visibility. Common in warehouses, offices, and corridors, ambient lighting ensures that employees can navigate safely and perform routine tasks without difficulty.

2. Task Lighting

Task lighting targets specific work areas where precision is required, such as assembly lines, inspection stations, or control panels. Adjustable fixtures and focused beams are typical features to provide adequate lighting for detailed tasks.

3. Accent and Safety Lighting

Accent lighting highlights critical zones, safety signs, or equipment locations, improving orientation and awareness. Safety lighting includes emergency exit illumination, hazard markers, and low-level path lights.

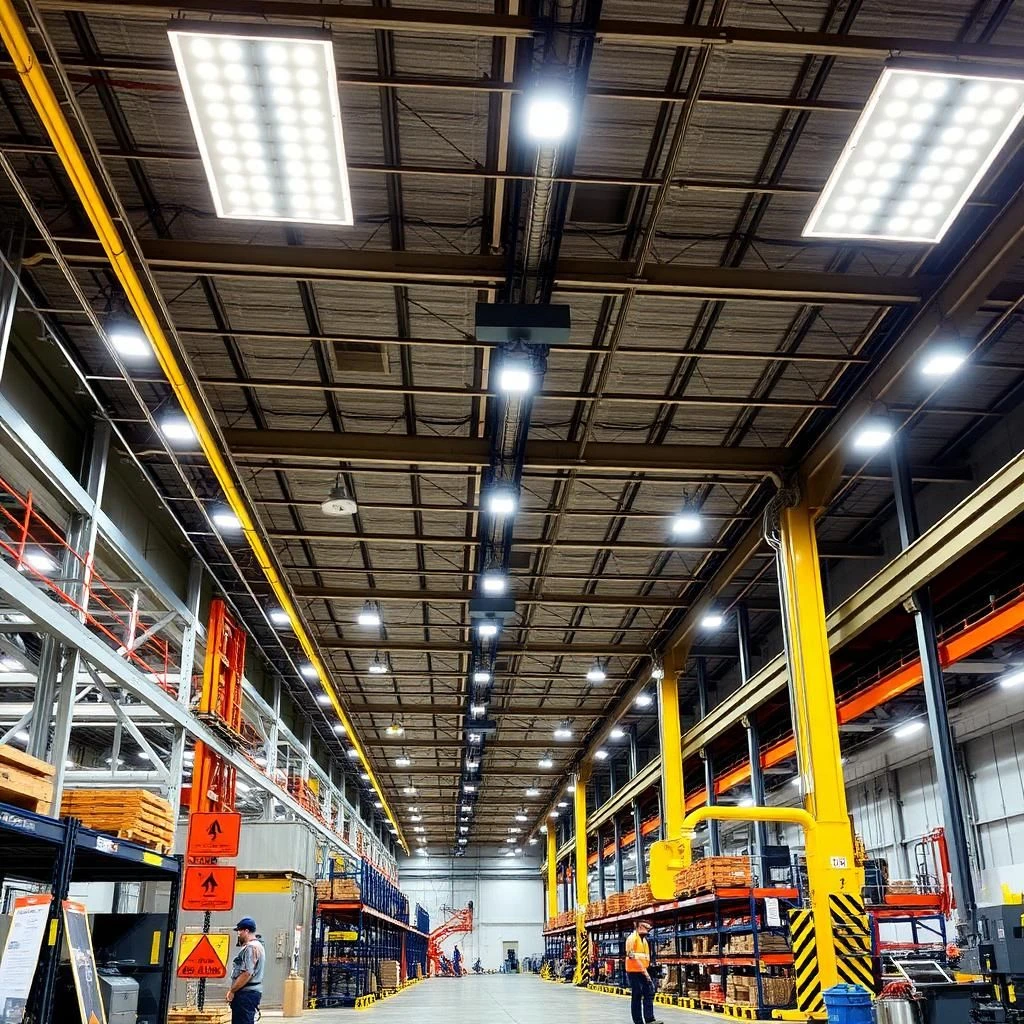

4. High-Bay and Low-Bay Lighting

High-bay lighting is used in facilities with ceilings higher than 20 feet, like warehouses and industrial plants, providing powerful, even illumination over large spaces. Low-bay lighting suits facilities with lower ceilings, such as workshops or retail areas.

5. Exterior and Site Lighting

Outdoor worksites require proper visibility for safety and security. Exterior lighting should consider:

- Perimeter lighting for security.

- Task-specific lighting for outdoor equipment or loading zones.

- Anti-glare designs to protect workers’ eyes and surrounding neighborhoods.

Modern Technologies Enhancing Worksite Visibility

Advancements in lighting technology have transformed the fundamentals of worksite visibility:

- LED and smart lighting: Adjustable brightness, color temperature, and energy-saving modes improve adaptability.

- Motion and occupancy sensors: Reduce energy consumption while maintaining safety.

- Emergency backup systems: Automated lighting during power outages ensures continuous visibility.

- Integrated IoT systems: Enable real-time monitoring, predictive maintenance, and centralized control over facility lighting.

By leveraging these technologies, facilities can achieve superior illumination with minimal energy use and maintenance overhead.

Lighting Design Considerations

Effective lighting begins at the design stage. Professionals must consider:

- Task requirements: Analyze workflows to determine illumination needs.

- Fixture placement: Avoid shadows, glare, and overlapping coverage.

- Color temperature: Cooler light (~5000K) enhances alertness, while warmer light (~3000K) improves comfort in break areas.

- Flexibility: Adaptable lighting zones allow for modifications as operational needs change.

Well-designed lighting enhances safety, reduces fatigue, and supports operational efficiency across diverse facility environments.

Training and Awareness

Even the best lighting systems are ineffective without awareness. Training employees on lighting zones, emergency exits, and hazard visibility promotes safe work practices. Organizations should include lighting orientation in safety briefings and ongoing training programs.

Conclusion

Mastering worksite and facility lighting fundamentals is critical for operational efficiency, safety, and compliance. Adequate illumination, uniformity, proper color rendering, energy efficiency, and adherence to safety standards form the backbone of effective lighting systems.

By combining modern technologies, proactive maintenance, and staff training, facilities can create safe, visible, and productive work environments. Strategically placed outbound references, like the Industrial Facility Lighting Guide, enhance your article’s authority without competing with your primary keyword.